Prototyping

The ‘fail-early, fail fast’ approach is commonly applied to product development. At Dawnlough we understand that the real purpose of this is not to fail but to be iterative.

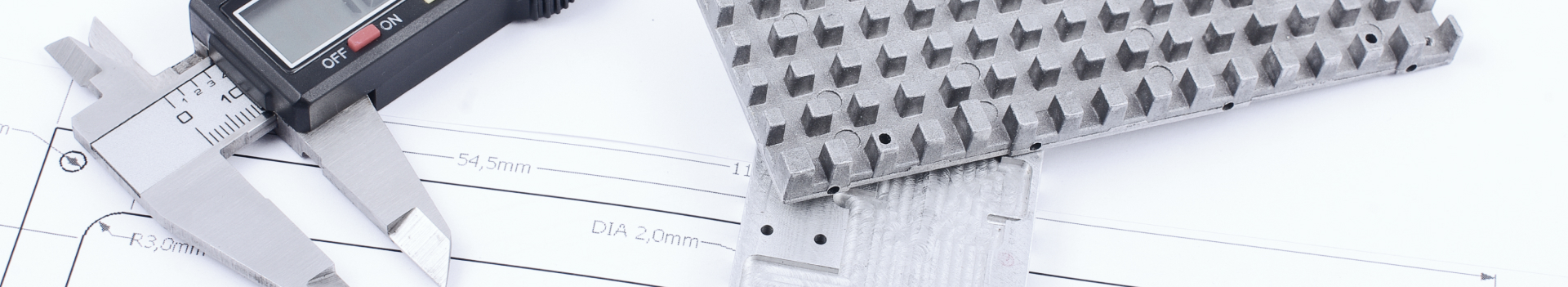

Quick lead times and responsive manufacture of prototypes is vital to enable our customers to build, test and accelerate their product development. Our ability to turn around low volume parts and assemblies with a fast response time is a crucially important support service to our customer start-up companies, R&D and process development departments.

In addition to manufacture and supply of prototype parts and assemblies, our design team provide mechanical design assistance, significantly Design for Manufacturability (DFM) expertise, that can make long and short-term cost savings for our client’s product development and manufacturing. These include DFM for machining, injection moulding, sheet metal and 3D printing manufacturing methods. Our design department also provides engineering resources for concept generation, prototype and full product designs tailored to our client’s needs.

Enquiry

Talk to us today to discuss your project requirements.