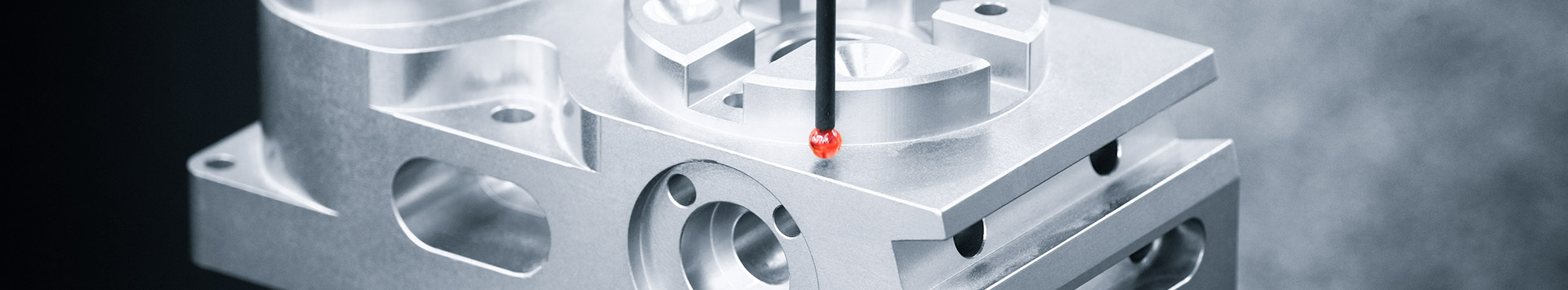

Metrology

We have a saying here in Dawnlough when it comes to component manufacture…

‘If you can’t measure it, you can’t make it’.

With this in mind, we have invested heavily in highly accurate (down to sub-micron) measurement systems that ensure we know that the components and assemblies we produce for our clients are correct and within specification. This is an integral part of our ability to provide premium manufacturing solutions that further instils high confidence and peace of mind for our customers.

Our Metrology Department is the backbone of quality control for manufactured components and assemblies in Dawnlough, and provides inspection aligned to whatever Acceptance Quality Limits are required for our clients’ purposes. It also enables our production facility to utilise Statistical Process Control (SPC) of manufacturing processes, and has expanded its capability to provide immediate post-process component inspection, directly to machine operators. This results in less waste and better-quality conforming product.

Additionally, we provide a service for our clients looking to identify root cause of failing, non-conforming product, or product demonstrating reduced functionality in the field. As part of this service, we provide objective analysis reports of product drawings, detailing & tolerancing strategy, and feature definition of critical & non-critical to quality features. We have substantial measurement capability, calibrated CMM and VMMs, to generate data driven measurement reports that can visually indicate where components may be out of spec, and to what degree. This has enabled our clients to actively remediate underlying or non-obvious issues with their products, as well as obtain independent inspection reports of production batch sampling. Our engineering team are ready and available to discuss your measurement and inspection needs.

Enquiry

Talk to us today to discuss your project requirements.